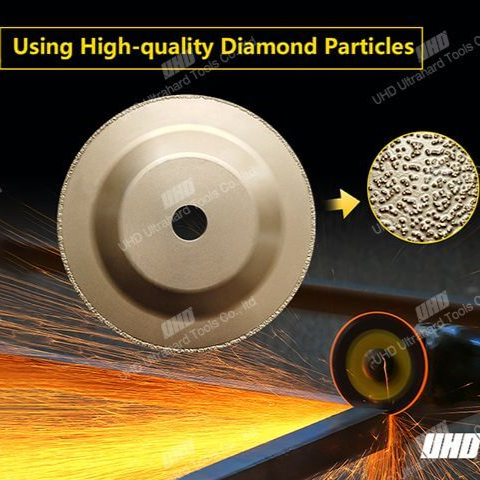

When it comes to precision grinding in metalworking and industrial applications, selecting the right diamond grit size isn’t just a technical detail—it’s a game-changer for both productivity and tool longevity. According to UHD’s global field data from over 120+ manufacturing sites, improper grit selection leads to up to 30% faster tool wear and 15% lower grinding efficiency. Here’s how to avoid that.

For softer materials like aluminum or mild steel, use finer grits (typically 60–120 mesh). This ensures smoother finishes and less heat buildup. For harder materials such as hardened stainless steel or ceramics, go coarser (40–60 mesh) to maintain cutting edge sharpness and reduce clogging.

Real-world insight: In a case study with a German automotive parts manufacturer, switching from 80-mesh to 60-mesh diamonds for grinding high-strength steel increased tool life by 27% while maintaining surface finish quality.

These aren't theoretical suggestions—they’re based on real-time feedback from our engineers across North America, Europe, and Asia. One Chinese CNC shop saw a 22% drop in rework rates after implementing these practices consistently.

Understanding how material affects grit behavior is key—not just for performance but also for cost control. A single misstep in grit choice can lead to unnecessary downtime, wasted coolant, and excessive tool replacement costs.

If you're running heavy-duty grinding operations in aerospace, medical devices, or ceramics, getting this right means fewer rejects, longer machine uptime, and better ROI per hour of operation. It’s not about buying more tools—it’s about using what you have smarter.

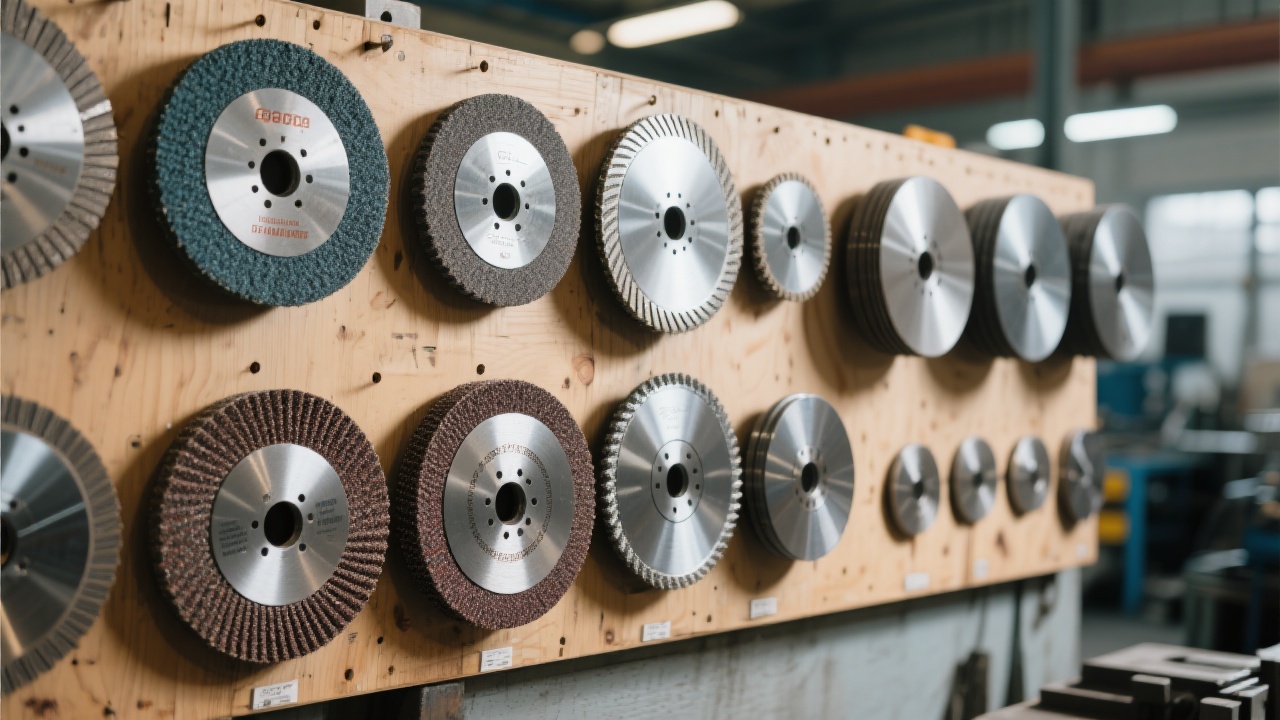

We’ve compiled all this into a free downloadable guide—complete with tables, checklists, and step-by-step workflows tailored for your production environment. Whether you're new to diamond grinding or optimizing existing processes, this resource will help you make informed decisions fast.

Download now and start improving efficiency today — no sign-up required.

Download the Technical Guide