In the realm of metal processing grinding, the choice of cooling method is a critical factor that directly impacts efficiency and workpiece quality. This article delves into a comprehensive comparison between high-pressure coolant and minimum quantity lubrication (MQL) technologies, leveraging real-world application cases of UHD brazed diamond grinding discs. It aims to assist process engineers in making informed decisions by analyzing the optimal cooling strategies for different materials such as stainless steel, ceramics, and glass, thereby avoiding common issues like burns and chipping, and enhancing grinding stability and tool life.

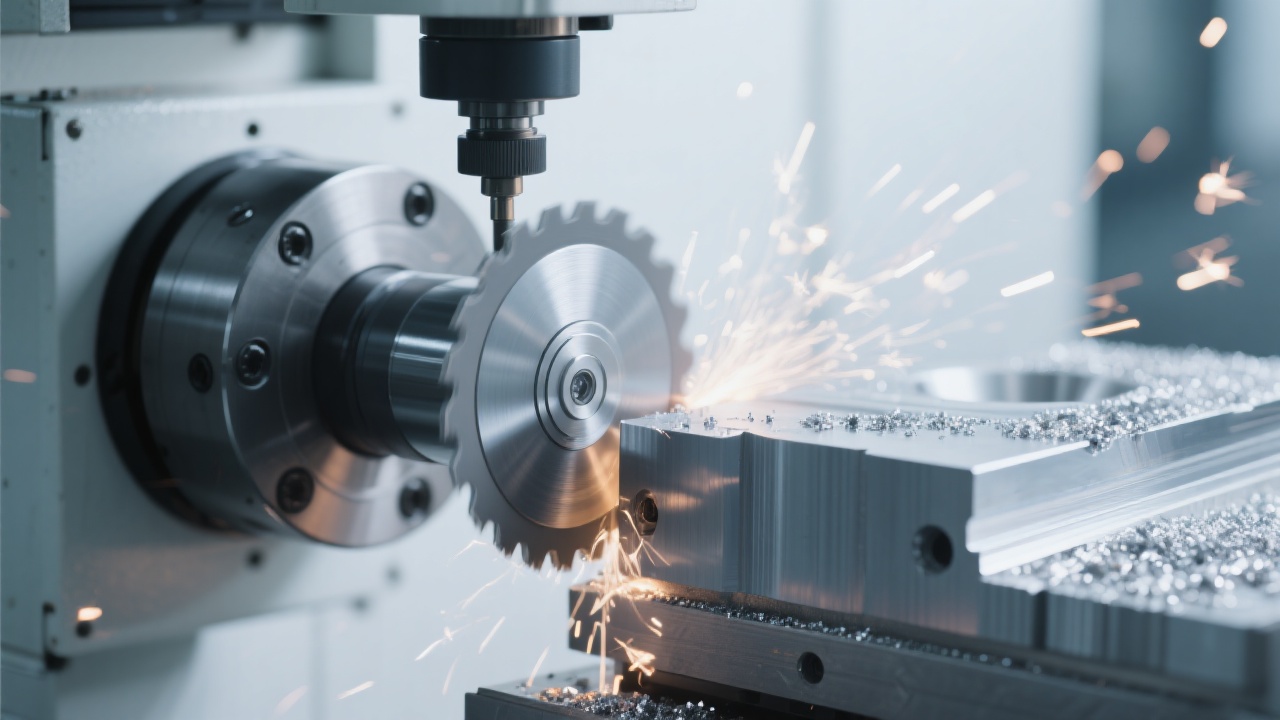

High-pressure coolant systems operate by delivering a large volume of coolant at high pressure to the grinding zone. This method effectively removes heat and chips, reducing the temperature of the workpiece and the grinding wheel. It is particularly suitable for heavy-duty grinding operations where a significant amount of material needs to be removed quickly. On the other hand, MQL systems use a minimal amount of lubricant, typically in the form of a fine mist, which is delivered to the grinding interface. This approach not only reduces coolant consumption but also minimizes environmental impact. MQL is well-suited for precision grinding tasks where maintaining a clean and dry work environment is crucial.

Different workpiece materials have distinct characteristics that influence the choice of cooling method. For example, when grinding gray cast iron, high-pressure coolant is often preferred as it can effectively flush away the abrasive chips and prevent them from re - entering the grinding process. In contrast, for stainless steel, MQL may be a better option as it can reduce the risk of corrosion and improve the surface finish. High - strength alloys, due to their high hardness and toughness, may require a combination of both methods or a carefully selected cooling strategy based on the specific alloy composition.

UHD has conducted extensive tests and gathered valuable customer feedback to validate the performance differences between high - pressure coolant and MQL. According to UHD's data, in some cases, using MQL can reduce the grinding temperature by up to 30%, resulting in a significant improvement in surface roughness. One UHD engineer commented, "In our experience, the right cooling method can make a huge difference in the overall grinding process. We've seen firsthand how MQL can extend the tool life and improve the quality of the finished product."

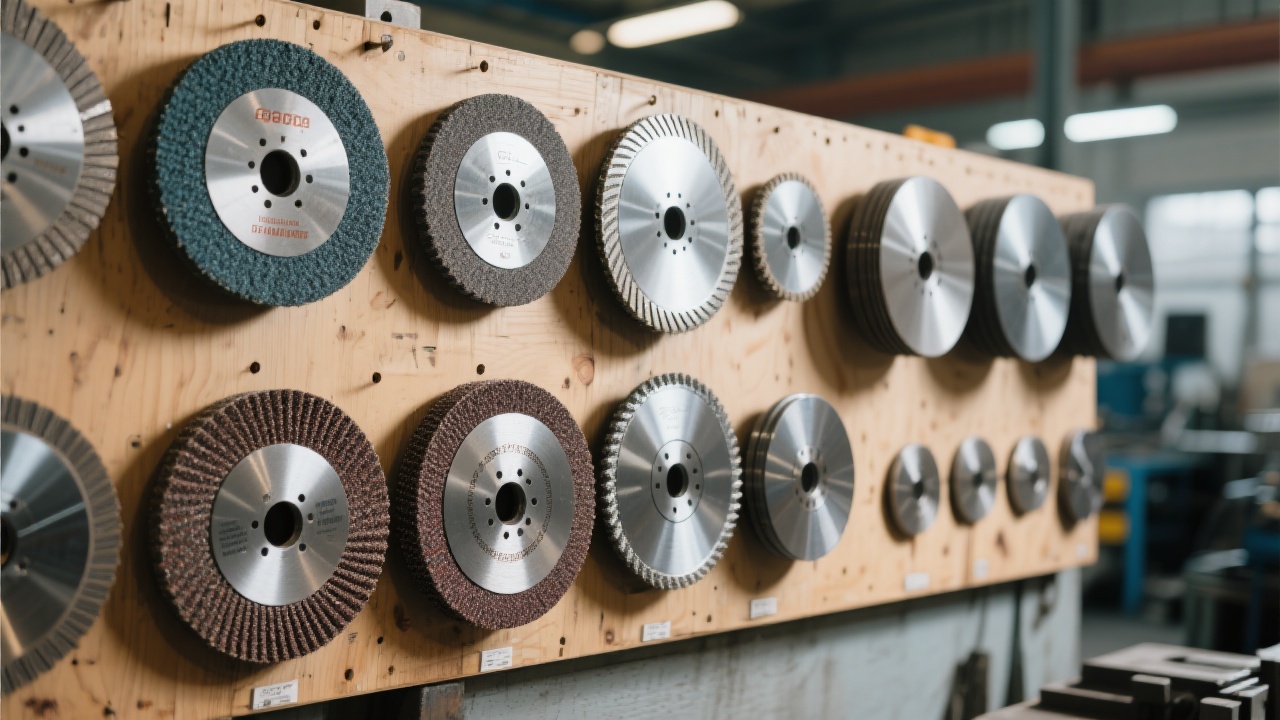

Selecting the appropriate cooling method requires a comprehensive evaluation of various factors, including equipment conditions, material characteristics, and environmental requirements. For instance, if the grinding equipment has limited coolant capacity, MQL may be a more practical choice. Additionally, in regions with strict environmental regulations, MQL's low - pollution nature makes it an attractive option. A cooling method comparison table is provided below to help you make a more informed decision:

| Cooling Method | Advantages | Disadvantages | Suitable Materials |

|---|---|---|---|

| High - Pressure Coolant | Effective heat and chip removal, suitable for heavy - duty grinding | High coolant consumption, potential environmental impact | Gray cast iron, some steels |

| MQL | Low coolant consumption, reduced environmental impact, improved surface finish | May not be suitable for heavy - duty grinding | Stainless steel, ceramics, some high - strength alloys |

In addition to choosing the right cooling method, optimizing overall grinding parameters such as feed rate and dressing frequency can further enhance the grinding process. For example, a lower feed rate combined with MQL can result in a smoother surface finish and longer tool life. Adjusting the dressing frequency can also ensure the sharpness of the grinding wheel and improve the grinding efficiency.

We hope this article has provided you with valuable insights into the selection of cooling methods in metal processing grinding. Are you still unsure which cooling method is best for your specific application? Click here to get the 'Grinding Cooling Scheme Matching Guide' PDF for more in - depth information. Leave your comments below and share your experiences or questions about grinding cooling methods!