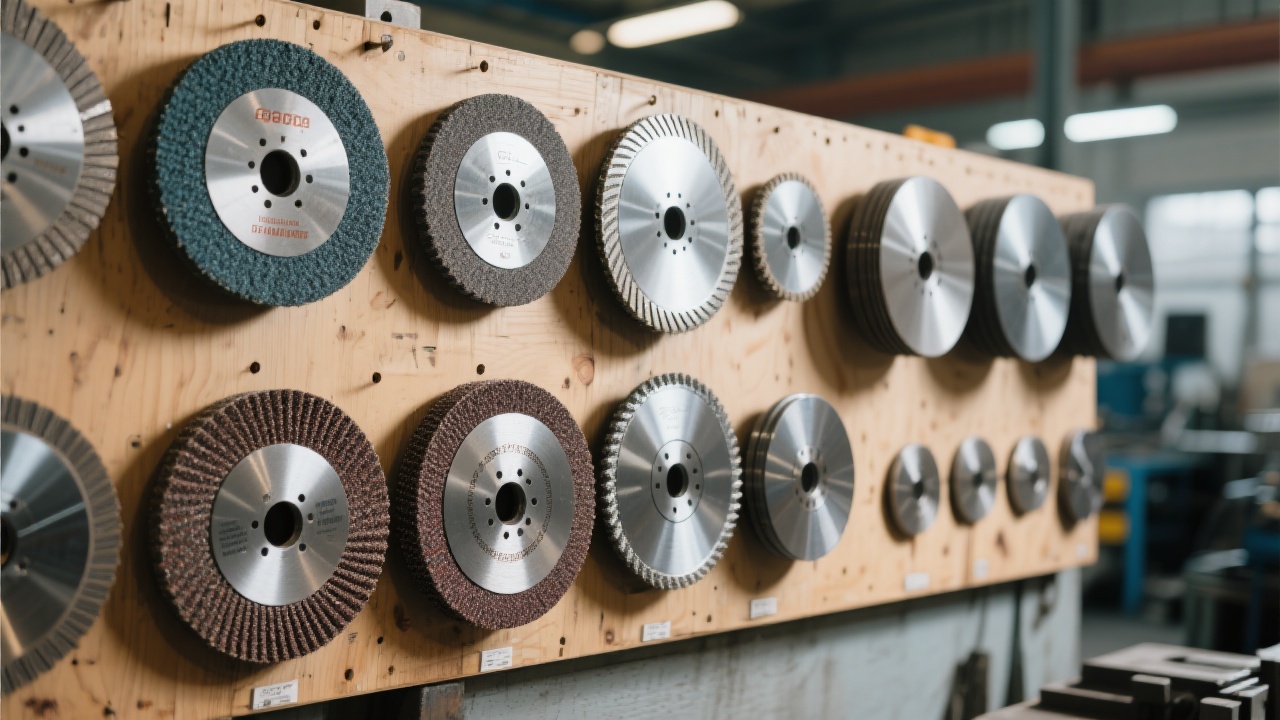

You may often encounter problems like short lifespan, burn marks, and chipping of your brazed diamond grinding discs. It's not the product's fault but the lack of attention to operational details. In this article, we'll delve into five practical techniques to improve grinding efficiency, which are all refined from the real working conditions of UHD's global customers. Let's start by looking at the common pain points you face.

You've probably noticed that your grinding discs don't last as long as expected, and there are often burn marks on the workpieces or chipping on the discs. These issues can significantly affect your production efficiency and cost. Have you ever wondered why these problems occur so frequently? You in the processing, have you ever encountered similar problems?

Choosing the appropriate diamond particle size based on the workpiece material is crucial. For example, when processing stainless steel, a larger diamond particle size may be more suitable as stainless steel is relatively soft and requires more aggressive grinding. On the other hand, when working on ceramics, a smaller diamond particle size can provide a finer finish. Here is a comparison table for better understanding:

| Workpiece Material | Suitable Diamond Particle Size | Application Scenario |

|---|---|---|

| Stainless Steel | Larger Size | General grinding, roughing |

| Ceramics | Smaller Size | Fine grinding, finishing |

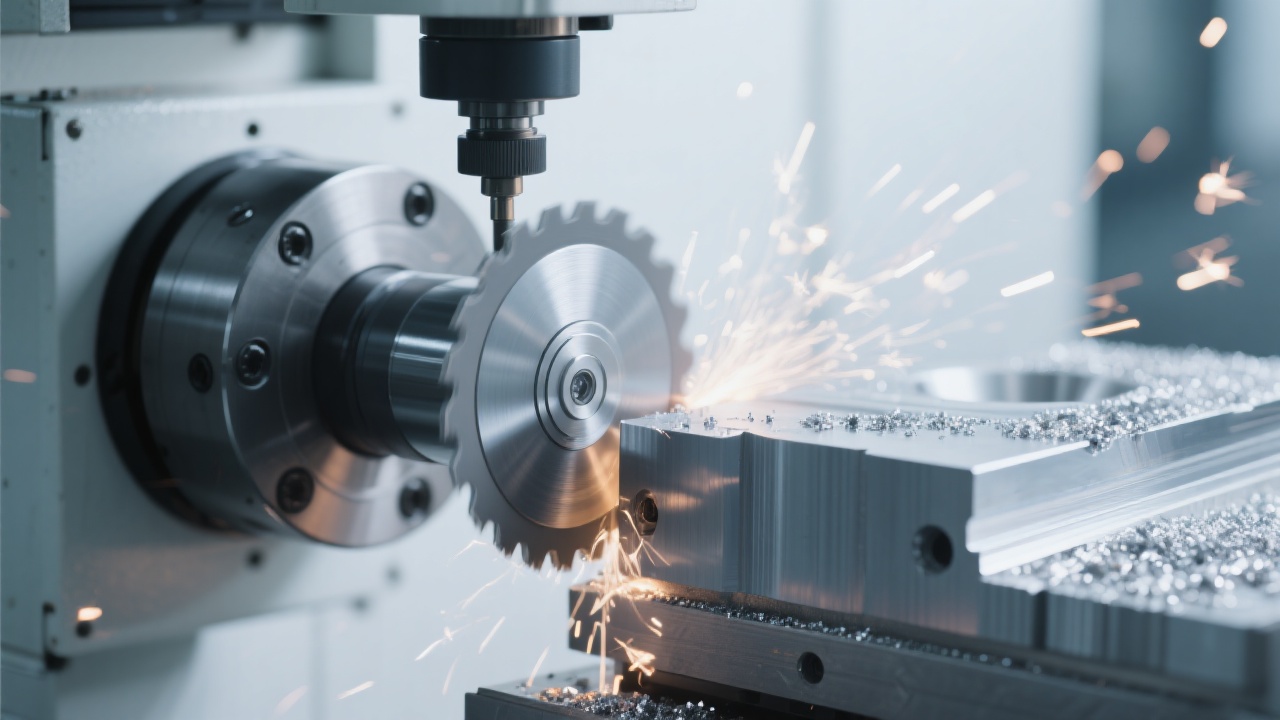

Temperature control is vital during the grinding process. UHD's实测 data shows that minimum quantity lubrication (MQL) and high-pressure coolant have different effects on temperature. MQL can provide a certain degree of lubrication and cooling with less coolant consumption, while high-pressure coolant can more effectively reduce the temperature in the grinding zone. For example, in some tests, when using high-pressure coolant, the temperature in the grinding zone can be reduced by up to 30% compared to using MQL alone.

Regular dressing of the grinding disc is essential. As the grinding disc wears, its surface will become dull, which can lead to problems like burn marks and chipping. By dressing the disc regularly, you can keep its cutting edge sharp. Based on the critical value of thermal cracks, it is recommended to dress the disc every 10 - 15 hours of continuous use. This can effectively prevent the occurrence of thermal cracks and extend the lifespan of the disc.

The feed rate is another important parameter. If the feed rate is too high, it can cause chipping of the grinding disc. Generally, a feed rate exceeding 20 mm/min is likely to cause thermal cracks and chipping. You should set the feed rate according to the workpiece material, diamond particle size, and other factors to ensure stable and efficient grinding.

Establishing a condition monitoring mechanism for the grinding disc can help you detect problems early and take corresponding measures. You can use some simple detection tools, such as a micrometer to measure the wear of the disc and an acoustic emission sensor to detect abnormal vibrations. By monitoring the condition of the disc regularly, you can avoid sudden failures and extend its lifespan.

In conclusion, a systematic approach is the key to efficient grinding, not just relying on a single device. By following these five techniques, you can improve grinding efficiency, extend the lifespan of your grinding discs, and save costs. If you want to learn more about industrial grinding parameter matching, click here to get the complete "Industrial Grinding Parameter Matching Manual".